FAQ

Here you will find answers to frequently asked questions. If you do not find what you're looking for, contact our support team.

No. CORA is not intended to replace the CAN bus. Rather, it is intended to be able to flexibly integrate actuators and sensors via cable (2-wire as the DL bus) or wireless (Cable Or Radio Access).

Nein, mit einer einzigen Ausnahme. Das Power-to-heat Set ATON ist für einen ganz bestimmten Anwendungsfall gedacht und wird deshalb mit einer Werksprogrammierung ausgeliefert.

Alle anderen frei programmierbaren Geräte der x2 Serie müssen erst speziell für die jeweilige Anwendung programmiert werden. Das können Sie selbst mit unserer kostenlosen Software TAPPS2 vornehmen oder von einer entsprechenden Firma vornehmen lassen. Sie können auch unser Programmierservice für das Fachhandwerk nutzen.

In unserer Programmbibliothek finden sich fertige Programmierungen inklusive Visualisierung, die Sie kostenlos herunterladen und verwenden können. Voraussetzung dafür ist, dass das Anlagenschema zum Schema unserer Programmierung passt. Es ist nicht ratsam, an diesen Programmierungen etwas zu ändern.

Für den Einstieg in die Programmierung bieten wir diverse Lern-Ressourcen an:

Files can be transferred to your controller using the SD card delivered alongside it. No additional devices are necessary for transfer.

The function overview is a graphics user interface for the UVR16x2 and can be created using the software TA-Designer. A step-by-step guide can be found at help.ta.co.at.

- The universal controllers (UVR1611, UVR16x2) are freely programmable and thus, the programming must be tailored to suit the conditions of the system it’s meant to regulate.

- Whether or not some specific boiler or heat pump can be regulated, depends on the signals it needs.

- Available inputs and outputs of our universal controllers are listed in their instruction manuals.

- Bus-systems specifically made by/for other produces are not supported.

- Of course, we can’t know all the different boilers and pumps available on the market, therefore we can’t give individual support on that topic.

If the graphics already featured in the TA-Designer aren’t sufficient, you can of course import your own. For the creation of graphics, there’s plenty of more or less pricey professional programs, or many good, free alternatives that will run on all operating systems and some even directly in your browser.

Yes, we offer two grades of seminars, for beginners and experts. Over two days each, you will be taught the programming and operation of the UVR16x2 controller. In the visualization seminar, an additional day teaches the handling of the software TA-Designer. This lets you create a user interface for the end consumer.

All of these seminars are solely in German.

On this page you can find the dates of seminars over the coming months.

Our Web Portal allows the access via internet to any system equipped with a C.M.I. that’s cleared for communication with the Web Portal. Access is available via your browser (Chrome, Firefox, Edge, Safari etc.) at https://cmi.ta.co.at or using the C.M.I. mobile app, available for free in the Google Play Store and in the Apples AppStore.

Yes.

You can download the app for free in the Google Play Store and in Apple's AppStore.

Despite all comfort, security may never fall short. Confidential data in a cloud or direct access to a system are unthinkable for us. The C.M.I. requests a connection to the Web Portal in short intervals, using an SSL secured connection, to inquire about new requests and only sends them out when demanded.

The C.M.I. itself only sends data to our servers if they’re requested at the Web Portal by an authorized user. Therefore, it’s not necessary to allow incoming connections, since the C.M.I. initiates connection. We use state of the art encryption of passwords at our Web Portal. The grade of security this provides is of course still dependent on the strength of your individual password.

The connection to our Web Portal can be entirely deactivated at any point. Access via LAN using your browser or app is still possible.

No.

We are developers and producers of regulation devices, extension modules and sensors. Qualified craftsmen (installers, electricians) are responsible for the proper installation and commissioning of our devices.

Whether the sensor or the controller is to blame for faulty functionality is easy to assess:

Let’s assume that Sensor 2 shows unrealistic measurements and Sensor 1 works as intended. In this case, swap the connections of sensors 1 and 2.

- If the fault follows the connection of the sensor (input 1 now shows faulty measurements and input works correctly), the fault is not on the controller’s side.

- If the fault does not follow the sensor’s connection (input 2 remains unrealistic) then the controllers is malfunctioning.

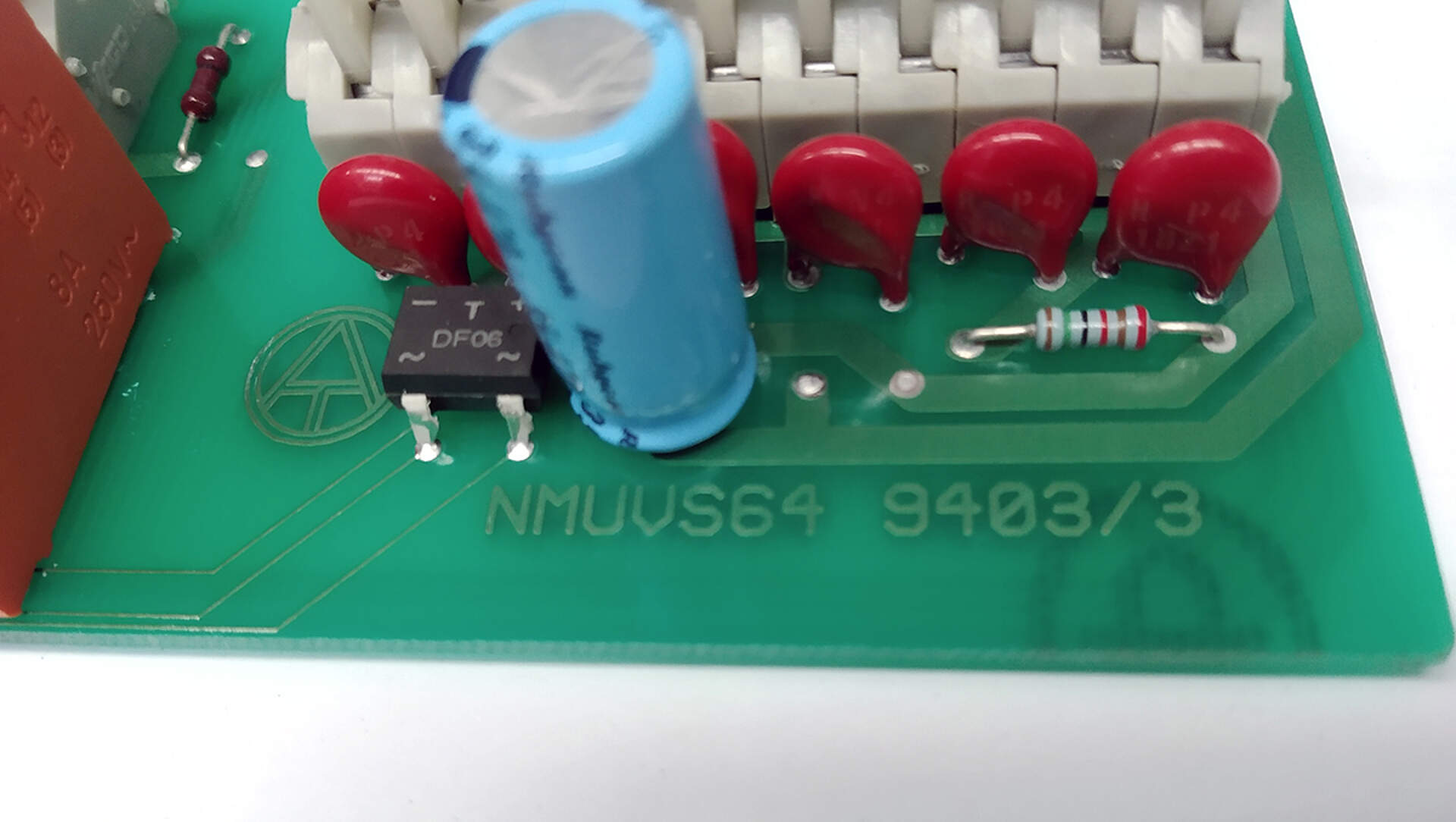

Seriennummern von sehr alten Geräten sind oft noch nicht in unserem System erfasst. In diesen Fällen fragen wir Sie dann meist nach der Platinen-Seriennummer. Wo diese zu finden ist bzw aussieht, sehen Sie auf dem folgenden Bild.

Definitely! Even if your device is no longer covered by the warranty, we will do our best to get it up and running again. Repairs cost between € 35 and € 65 depending on the device. Further information can be found in our repair and service conditions. In the unlikely event that we are unable to repair your device, we will keep you informed and endeavour to find a suitable solution.

In general, repaired devices leave our factory again within a week. Whilst we strive to deal with all complaints as quickly as possible, there may sometimes be a slight delay due to the extent of the fault and complexity of the tests required. We ask for your understanding in this matter.

Every device initially undergoes an electric strength test in accordance with EN 60950. This involves using a test voltage of 4.6 kV to check whether there is an unintentional connection between the live or neutral conductor and the sensor earth.

Following this, the actual test program is started, which measures all inputs and outputs, one after the other. If a fault is detected, this is shown on the controller display screen. This provides the production team member assigned to the device with a starting point from which to begin the repair work. If none of the tests are able to detect a fault, yet the fault description clearly indicates a malfunction, a member of the quality assurance team performs a further (more "in-depth") test.