New control system for public buildings

The two buildings of the city council for Neulengbach (near Vienna) houses, among others, the town hall, construction authorities, several apartments, offices, a Kindergarten, district court and an event hall. The masonry is from as late as the 17th century, newer parts of the building from the early 20th century.

The building complex with an area of more than 6,600 m² is supplied via a district heating system, with some buildings also supplied with smaller local heating networks. Domestic hot water production is decentralised.

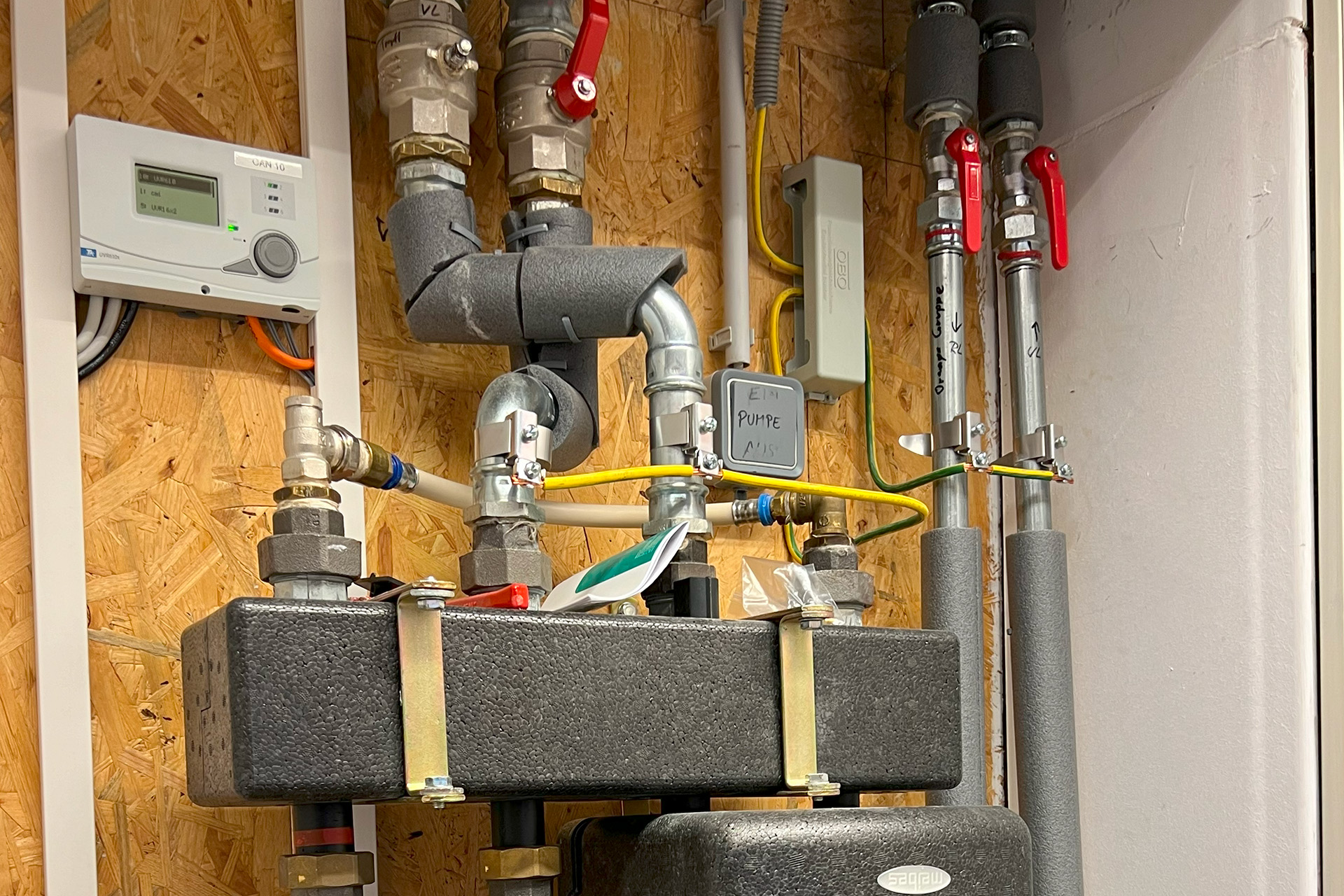

As so often, even after several steps of renovation on different spots, the actual heating demand was no longer comprehensible. In the past, every section of the complex had its own independent distributor in use, none of which communicated with one another. A "summer/winter switchover", for example, could be carried out by unplugging and replugging the pump's power – depending on outdoor temperatures. Energy losses were understandably high. When accessing the basement, heat losses from buffer tank and pipes could already be felt.

The energetic optimisation

In 2022, the city council and mayor Jürgen Rummel decided to improve the energy situation of these buildings. The company Bauer heating pump systems of Pielachtal, Austria, was contracted.

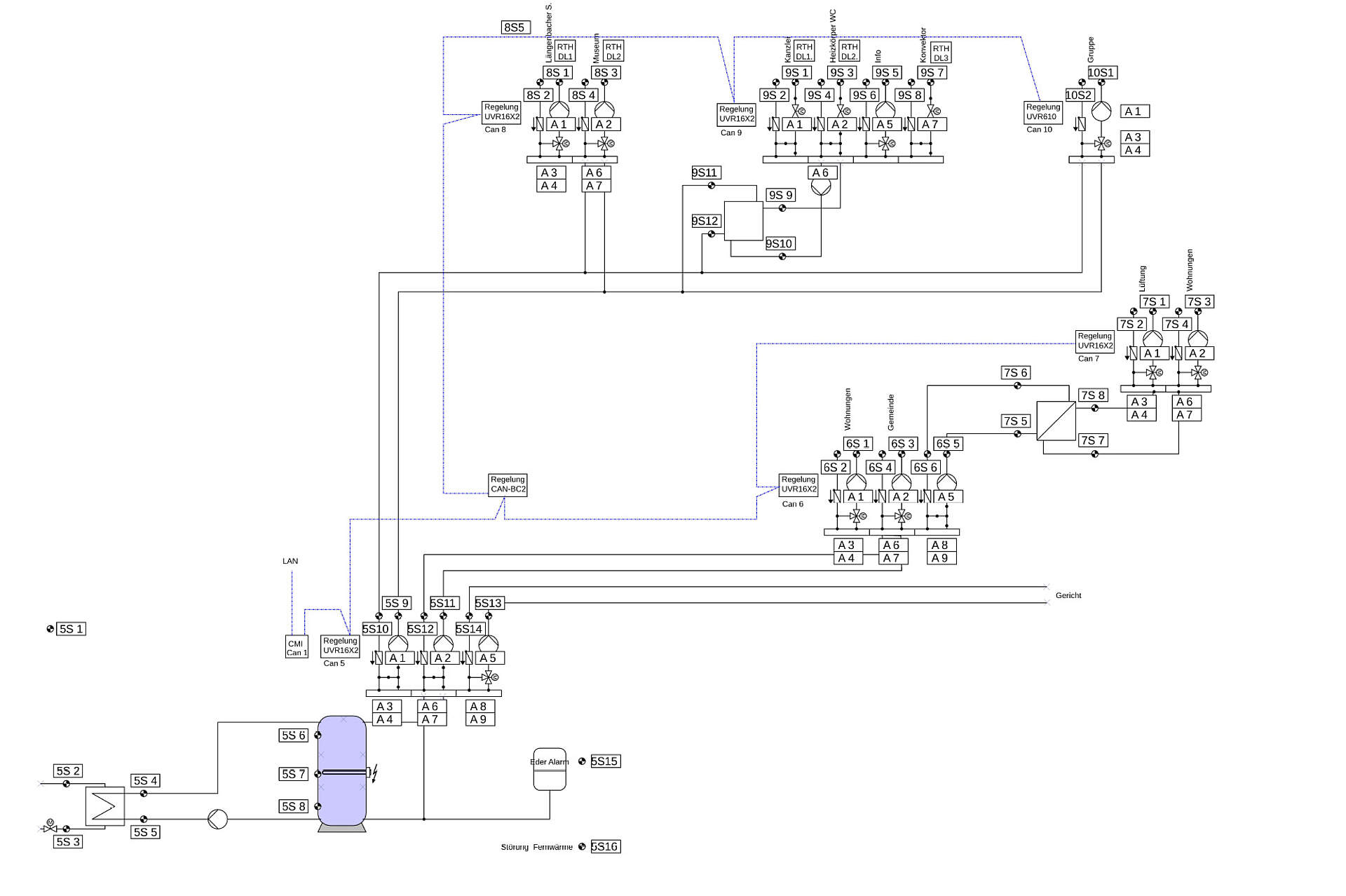

It quickly became clear, that only a primary controller could realise this optimisation. The choice fell on the freely programmable universal controller of the "TA". As a central controller, one UVR16x2 by the district heating transmission station was used. Every building or heating distributor received further controllers, a UVR16x2 or UVR610 based on requirements.

Communication on the level of the control technology now makes it possible to calculate the maximum required temperature demand. Based on different usage scenarios of building sections, from Kindergarten to office or event hall, the relevant heating circuits with differing temperature levels for convectors, ventilation, radiatiors and panel heating are supplied. The new control tech now allows this to be realised, alongside a graphics display via CMI gateway for the building technicians.

Naturally, the pumps and valves are controlled independently of use and based on climate. If certain thresholds are crossed, notifications are sent via e-mail to ensure seamless heating operation.

When accessing the basement, where the district heating transmission station is also placed, the air already feels more comfortable than before the renovation.

The energy savings are already clearly felt after just a single cold season's heating. The primary controller saved 100MWh of heating energy in 2023/2024 when compared to the annual average of the past 4-5 years. That's about 20-25% of overall demand.

Controllers

- 5 UVR16x2

- 1 UVR610

- 1 CMI

- 1 CAN-BC2

- Sensory equipment

System

- 6,600 m² total area

- Heating supply via district heating

- 12 heating circuits

- 1000 liter buffer tank

This project was realized by:

Bauer heating pump systems

Franz Bauer GmbH

Gewerbepark 5-7

A-3202 Hofstetten

https://www.bauer.eco