Shared local heating

Does every house really need its own heating system?

A new building with four rental apartments and a commercial unit was to be built in the place of a now demolished former farmyard. The old house had an aged gas-fired water heater, which was classified as a risk after high waters. The declared goal was to lower incidental costs without relinquishing comfort.

Considerations

The following draft was made, together with project partners:

- 20.5 m2 vacuum tube thermal solar panels and 5,000-liter buffer cylinder

- 96,5 kW central gas-fired heater

- Shared local heating between buildings

Most manufacturer’s solutions weren’t flexible enough. During operations, experiences would be gained that allow for optimisations, which in turn necessitates adjustments to the system’s software. The solar panels should primarily supply to the newly constructed house. Any excess heat would be supplied to surrounding buildings. This helps reduce operating hours of the heater and any excess solar power isn’t wasted.

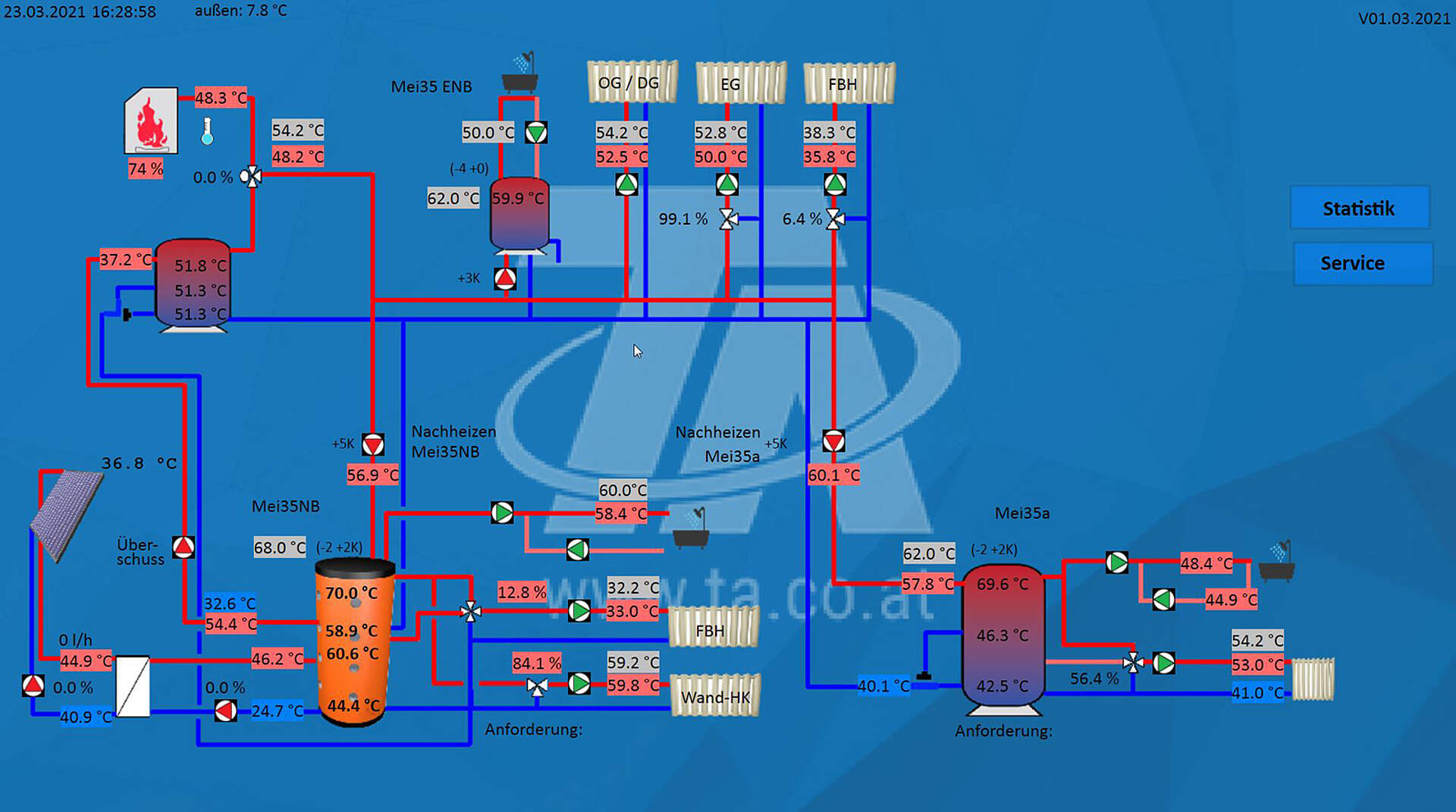

Implementation using x2 devices

The UVR16x2 was the controller of choice. Every house received a controller with touchscreen interface for local visualisation and parameterisation. Devices communicate via CAN bus. A C.M.I. rounded up the visualisation and allows for remote access, but also sends out e-mails in case of malfunctions. It also offered a convenient way of data logging during operation and system monitoring, which proved useful and allowed for efficient operation. The solar panel and some short-term changes to the system’s software allowed for almost continuous heat supply even during construction.

System

- Central gas-fired heater (96.5 kW), regulated via 0-10V signal

- 20.5 m2 vacuum tube thermal solar panels, 5000-litre buffer cylinder

- Shared local heating between buildings

This project was realised by:

SPS Frank Weise (Programming)

Thomas Wolf Haustechnik (Installation)

ed energie.depot GmbH (Solar thermal system)